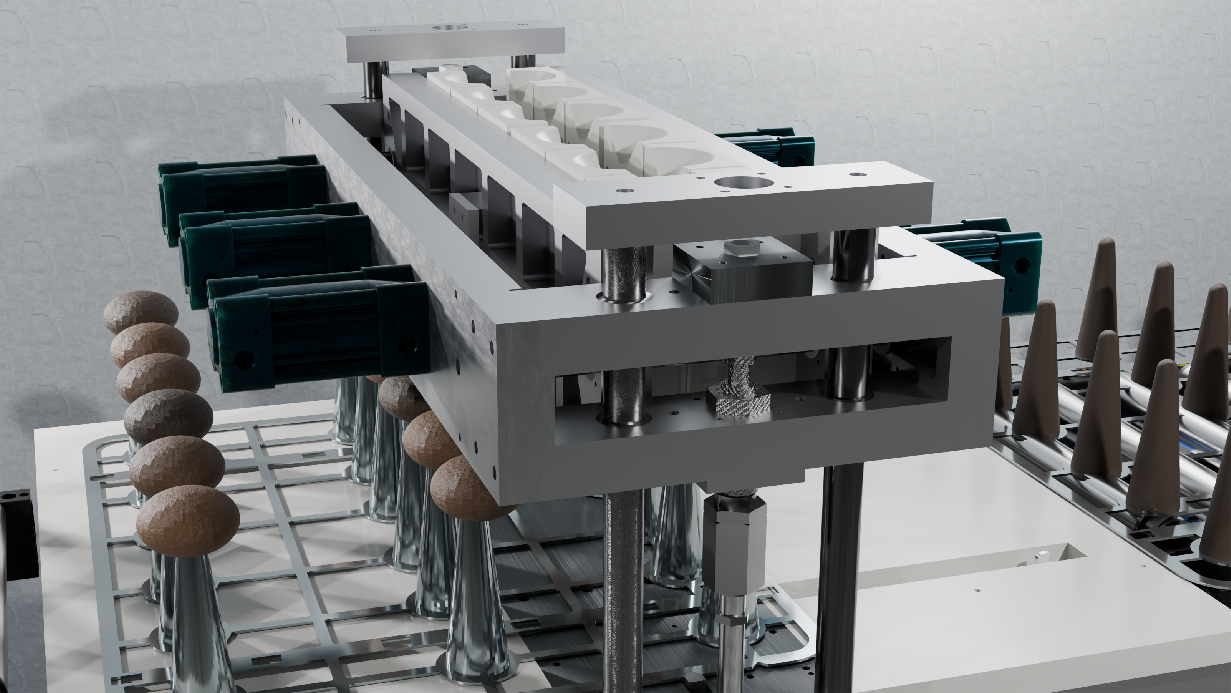

Industrial systems for conical dough production and beyond

The Conical Production System

Modular architecture. Industrial precision.

The conical production system is built as a modular industrial platform, structured in three integrated stages that ensure geometry control, surface consistency, and scalable throughput.

- Forming: The core forming unit shapes dough into uniform conical geometry with controlled pressure, rotation, and alignment. This stage defines structural integrity, dimensional accuracy, and repeatable output.

- Brushing: An automated brushing module applies coatings, glazing, or functional surface treatments. This ensures consistent texture, controlled browning, and optimized baking performance.

- Topping: The topping system distributes seeds, grains, or surface elements with precision, maintaining uniform appearance and flavor balance across high-volume production cycles.

Each module can operate independently or as a fully integrated production line, depending on capacity requirements and operational setup..

This modular design allows bakeries to implement the system progressively or deploy it as a complete automated solution — without compromising geometry standards or production efficiency.

The result is not simply shaped dough. It is controlled industrial geometry, repeatable at scale.

Production Configurations

Scale by Design

The conical production system is available in three configurations, engineered to serve different production environments while maintaining identical geometry standards and product integrity.

Small Version Compact. Flexible. In-house production. Designed for artisan bakeries, restaurants, and small-scale producers wishing to manufacture conical dough products internally.

- Compact footprint

- Semi-automated operation

- Ideal for fresh, on-site production

- Suitable for controlled daily output

Standrad Version: Mid-range industrial capacity. Engineered for regional distribution and structured foodservice supply, capable of producing up to 25,000 pieces per day.

Integrated forming, brushing, and topping modules

Optimized for consistency and workflow efficiency

Suitable for expanding production facilities

This configuration balances output capacity with operational control.

Large Version: Fully automated industrial line. Designed for high-volume manufacturing environments, capable of producing up to 80,000 pieces per day.

Complete automation

Continuous production cycles

Industrial-grade throughput

Suitable for national and international distribution

This is a full-scale production infrastructure, built for industrial expansion.

Regardless of configuration, the system preserves identical cone geometry, ensuring consistency across different production scales. Scalability does not alter the product. It multiplies it.

Licensing and Industrial Partnership

Controlled expansion through technology

The conical production system is available under structured licensing agreements for qualified industrial partners and bakeries.

Our objective is not to distribute equipment indiscriminately, but to build a controlled production ecosystem that preserves product integrity, geometry standards, and brand alignment.

Through licensing, partners gain access to:

The patented conical forming technology

Operational integration guidance

Structured production standards

Ongoing technical support

This model enables geographic expansion while maintaining consistency across markets and production environments.

Licensing is not simply access to machinery.

It is participation in a defined industrial system.

Each partner becomes part of a coordinated network — aligned by shared standards, protected technology, and long-term collaboration.

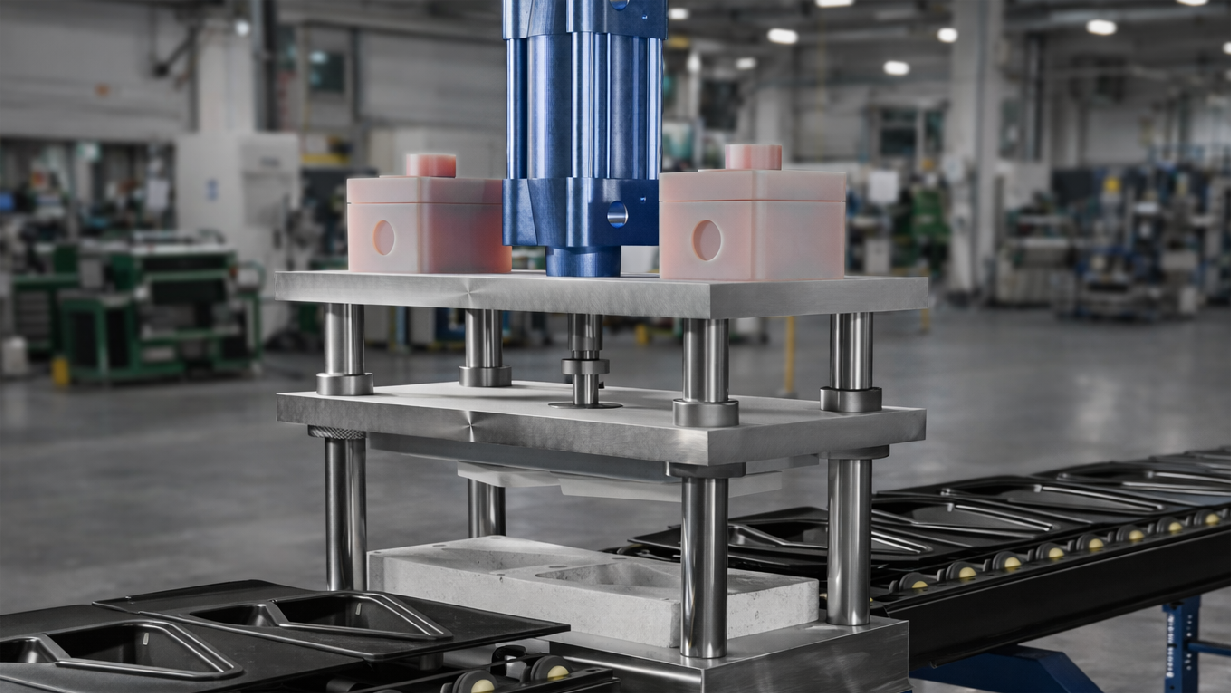

Beyond the Cone

Engineering new dough geometries and production systems

The conical forming system was our first industrial breakthrough — not the boundary of our capability..

Global Golden Spark operates as an engineering-driven food innovation laboratory. We design industrial equipment not only to produce products, but to define how those products are structured, scaled, and controlled.

Beyond conical production, we have developed systems capable of manufacturing:

- Dough cups engineered for filling stability and structural integrity

- Precision-formed pizza bases and structured dough slices with controlled thickness, edge definition, and uniform bake performance

- Custom geometric bakery formats tailored to specific culinary and commercial applications

Our work is not limited to predefined formats. We design and develop custom industrial equipment built around specific operational requirements — from shaping modules to automated preparation lines and fully integrated production systems.

If a product requires a new production method, we engineer the method.

Innovation, for us, extends beyond food concepts.

It includes the machinery, process logic, and industrial infrastructure that make new categories possible.

This is not expansion of equipment. It is the continuous evolution of production geometry.